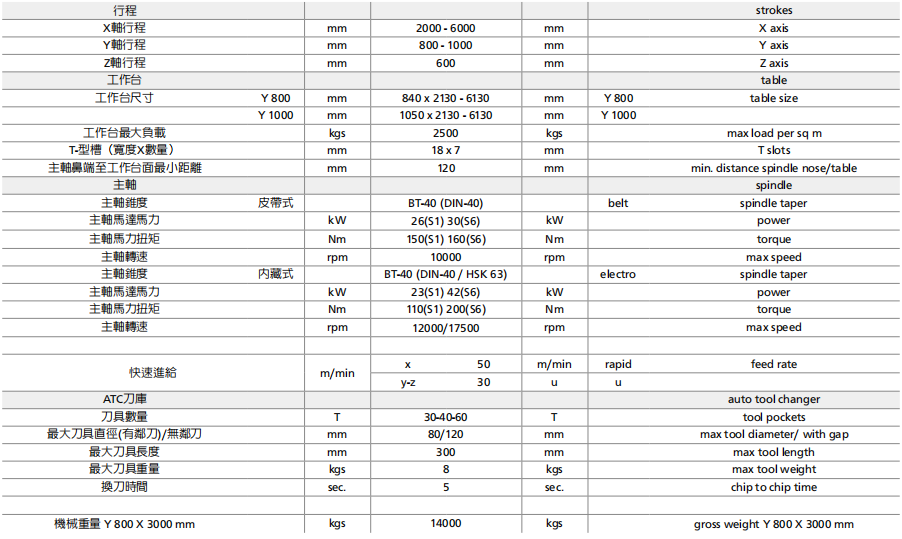

动柱式立式加工中心机

商品详情

KOBRA的高刚性机械结构完美保证其性能表现及绝佳之加工精度。独特的动柱式搭配固定工作台设计提供下列应用之可行性:

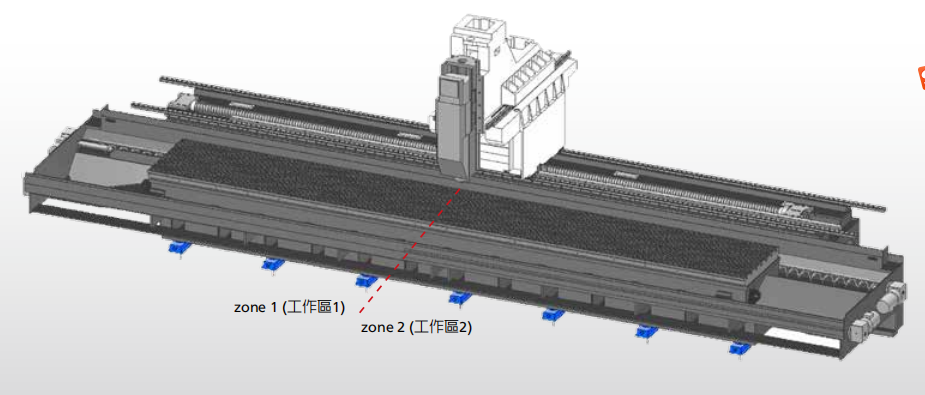

-x轴模组化设计,可提供行程范围自2000mm到6000mm-提供弹性且广泛的工件变化性,使用者可自行规划工作区为独立工作区或双工作区甚至多工作区

-亦适用于加工重型且庞大的工件

-可加装第四轴旋转工作台,避免任何x轴行程损失

-可加装特别设计之夹治具避免干涉问题产生

KOBRA's high-rigidity mechanical structure perfectly guarantees its performance and excellent processing accuracy. The unique moving column type with fixed table design provides the feasibility of the following applications:

-X axis modular design can provide a stroke range 2000mm to 6000mm

-Also suitable for processing heavy and huge workpieces

-The fourth axis rotary table can be installed to avoid any x-axis travel loss

-Specially designed clamps can be added to avoid interference problems

KOBRA提供两种不同之主轴结构:

-皮带式主轴:转速10000rpm,主轴虽度#40-内藏式主轴:转速12000rpm(选配18000rpm),主轴虽度#40或HSK-A63

KOBRA offers two different spindle structures:

-Belt spindle: spindle 10000rpm, spindle though # 40-built-in spindle: spindle 12000rpm (optional 18000rpm), spindle though # 40 HSK-A63

KOBRA的结构可规划为双工作区,工作区一搭配第四轴旋转工作台,工作区二则使用固定工作台,除了可增加机器加工应用弹性外,亦大幅提升加工效率。可达成一次性五面或五轴加工,大容许旋径为4700 H400mm

The structure of KOBRA can be planned as a dual work area. Work area 1 is equipped with a fourth-axis rotary table, and work area 2 uses a fixed work table. In addition to increasing the flexibility of machine processing applications, it also greatly improves processing efficiency. One-time five-sided five-axis machining can be achieved, the maximum allowable rotation diameter is 4700 H400mm。

采用刀臂式自动换刀系统,刀对刀换刀时间3秒。刀库随x轴同时移动,任何不同的应用都可达到快速操刀的需求。固定工作台结构让操作者更易于装卸及检验工件,且可极简清理工作区铁屑及切削液的时间。

The knife arm type automatic tool change system is adopted, and the tool change time is 3 seconds. The tool magazine moves with the x-axis at the same time, and any different application can meet the needs of rapid tooling.

The fixed table structure makes it easier for the operator to load and unload and inspect the workpiece, and it can simplify the time for cleaning the iron scrap and cutting fluid in the work area.